Net Positive Suction Head (NPSH) Margin

June 13, 2017

When selecting a pump, it is extremely important to ensure that the net positive suction head available (NPSHA) is greater than the net positive suction head required (NPSHR) of the pump to prevent cavitation.

NPSHA is the amount of absolute suction head available in feet of liquid at the first stage impeller datum minus the absolute vapor pressure of the liquid.

NPSHA = h,atm + h,s – h,vp = ft of liquid

Where:

h,atm = atmospheric pressure head = ft

h,s = total suction head = h,gs + h,vs + z,s = ft

h,gs = suction gauge head = ft

h,vs = suction velocity head = ft

z,s = elevation from the gauge centerline to first stage impeller datum* = ft

(*The “J” dimension shown in the National Pump Company Engineering Catalog for bowl assembly dimensions shows the location of the first stage impeller datum)

h,vp = liquid vapor pressure

NPSHR is a minimum NPSH given by the pump manufacture for the pump to achieve the specified performance. This value may be equal to the NPSH3 of the pump or many contain a margin above the NPSH3 of the pump depending on the manufacture.

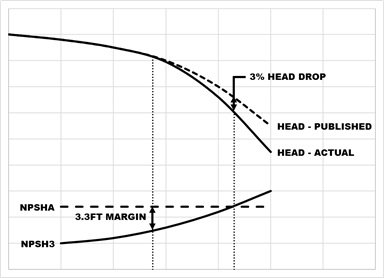

NPSH3 is the net positive suction head required resulting in a 3% loss of total head at the first stage impeller due to cavitation (Figure 1). This is the NPSH value determined during testing. National Pump Company publishes a NPSH3 curve, which is labeled as NPSHr in PumpFLO.

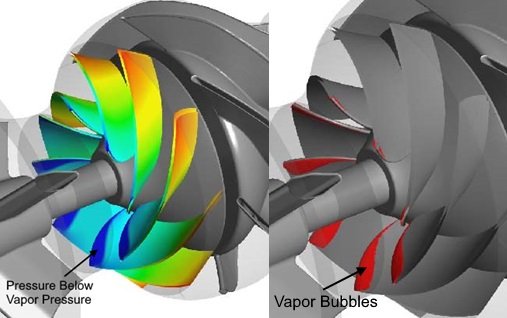

If a pump is design with an insufficient margin between the NPSH3 of the pump and the NPSHA, cavitation will occur. Cavitation is due to the pressure within pump dropping below the vapor pressure of the liquid which results in the liquid becoming a vapor. This vapor reduces the area where the liquid can flow causing the loss in performance. As the vapor travels though the pump, the pressure increases causing the vapor bubbles to collapse returning to a liquid. This collapse results in noise, vibration and material loss reducing the pump life.

The Hydraulic Institute has a guideline for NPSH margin, ANSI/HI 9.6.1. This guideline discusses a number of items which influence the needed margin along with recommended margins. The recommended margin is based on either the:

- NPSH Margin Ratio which is the NPSHA divided by the NSPH3 or

- NPSH Margin which is the NPSHA minus the NPSH3

While the recommendations vary based on application, size, materials and operating region, a 3.3-foot (1.0-meter) margin or 1.1 ratio, whichever is greater, is typically acceptable (Figure 1).

Figure 1 – Curve Showing Head Performance and NPSH3 at a Specified NPSHA

Ensuring an adequate NPSH Margin between the NPSH3 of the pump and the NPSHA will ensure the pump performances properly.

Figure 2 – CFD Analysis Showing Pressure Gradient Thru the Impeller (left) and Cavitation Bubble Sheet (right)